Glasgow Products

Division of Steinen

29 East Halsey Rd.

Parsippany, NJ 07054

Phone: 973-887-6400

Fax: 973-887-4632

Division of Steinen

29 East Halsey Rd.

Parsippany, NJ 07054

Phone: 973-887-6400

Fax: 973-887-4632

Air Conveying Concept

|

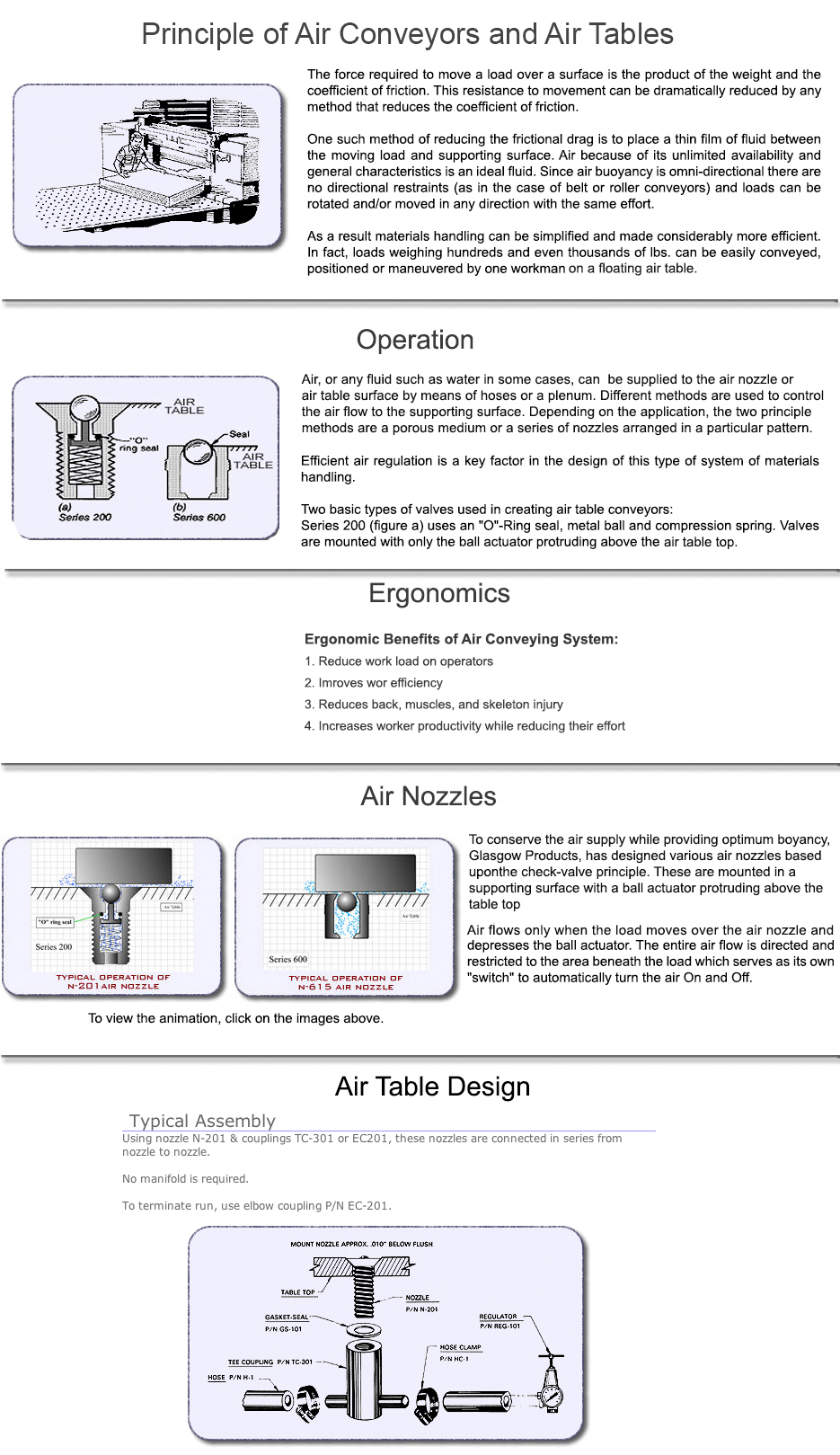

The full area (30" X 30"=900 Square Inches) is not operational at start-up when the load is setting on the table. At start-up, the only lift area is the combined area over the nozzles ( 0.78" sq./ nozzle). Assuming that nozzles are on 6" centers, there would be 16 nozzles under this load of 30" X 30". Therefore each of the 16 actuated nozzles has to lift 24 lbs. With this info as background, it is suggested that a shallow spotface 2" in diameter by 1/64" (0.020") deep be formed into the table surface where each nozzle will be located, with each nozzle mounted slightly below flush with the base of this spotface. With the nozzle in place in the spotface, an air lift pad of 3.14 square inches is created. If, for example, an air pressure of 8 PSI were applied to the nozzles, each nozzle would now provide a lift of over 25 lbs. (3.14 x 8 = 25.1 lbs.). The total lift of the 16 actuated nozzles would be 400 lbs. (16 nozzles X 25 lbs./nozzle=400 lbs.) with plenty of leeway to increase the regulator setting in case the load was increased. .

The full area (20" X 25"=500 Square Inches) is not operational at start-up when the load is setting on the table. At start-up, the only lift area is the combined area over the nozzles ( 0.78" sq./ nozzle). Assuming that nozzles are on 6" centers, there would be 20 nozzles under this load of 20" X 25". Therefore each of the 20 actuated nozzles has to lift 0.35 lbs. With this information as background, it is suggested that the 20 nozzles are set up in a rectangle shape at 6 inch centers. With the nozzles in place, an air lift pad of 0.78 square inches is created. If, for example, an air pressure of 1 PSI were applied to the nozzles, each nozzle would now provide a lift of 0.78 lbs. (0.78 x 1 = 0.78 lbs.). The total lift of the 20 actuated nozzles would be 15 lbs. (15 nozzles X 0.78 lbs./nozzle=15.6 lbs.). .

The full area (25" X 25"=625 Square Inches) is not operational at start-up when the load is setting on the table. At start-up, the only lift area is the combined area over the nozzles ( 0.78" sq./ nozzle). Assuming that nozzles are on 6" centers, there would be 25 nozzles under this load of 25" X 25". Therefore each of the 25 actuated nozzles has to lift 3 lbs. With this info as background, it is suggested that the 25 nozzles are set up in a square pattern at 6 inch centers. With the nozzles in place, an air lift pad of 0.78 square inches is created. If, for example, an air pressure of 4 PSI were applied to the nozzles, each nozzle would now provide a lift of 3lbs. (0.78 x 4 = 3.12 lbs.). The total lift of the 25 actuated nozzles would be 78 lbs. (25 nozzles X 3.14 lbs./nozzle=78 lbs.). For additional lift, increasing the regulator setting by 1 PSI adds 25 lbs. in load carrying capacity of the nozzle table. |

|